630T powder forming hydraulic press 630T salt brick machine production line

The 630-ton salt brick machine powder molding hydraulic press production line can achieve a high-efficiency powder molding process and is equipped with advanced hydraulic technology, which greatly imp

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 630-ton salt brick machine powder molding hydraulic press production line can achieve a high-efficiency powder molding process and is equipped with advanced hydraulic technology, which greatly improves production efficiency.

Equipment and links:

Mixer: Used to fully mix salt, mineral licking brick additives and other raw materials to ensure uniform ingredients.

Lifting pipe: Lift and transport the mixed materials to the storage bin.

Storage bin: stores the mixed materials and provides raw materials for the subsequent pressing process.

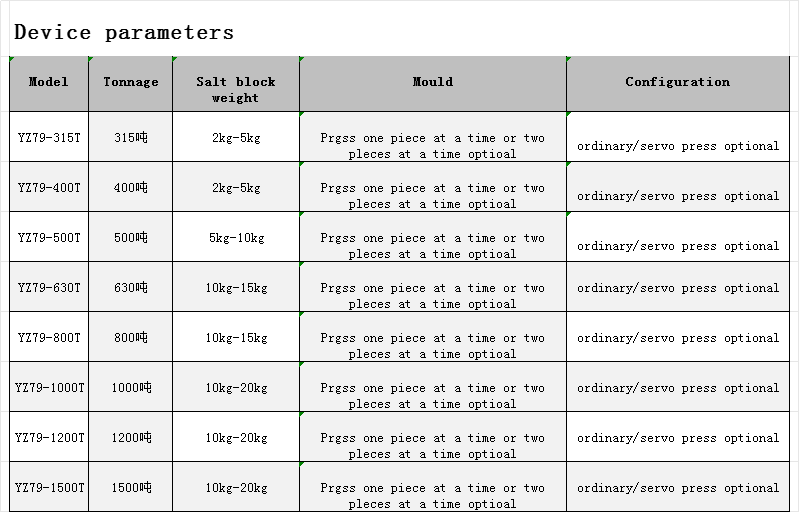

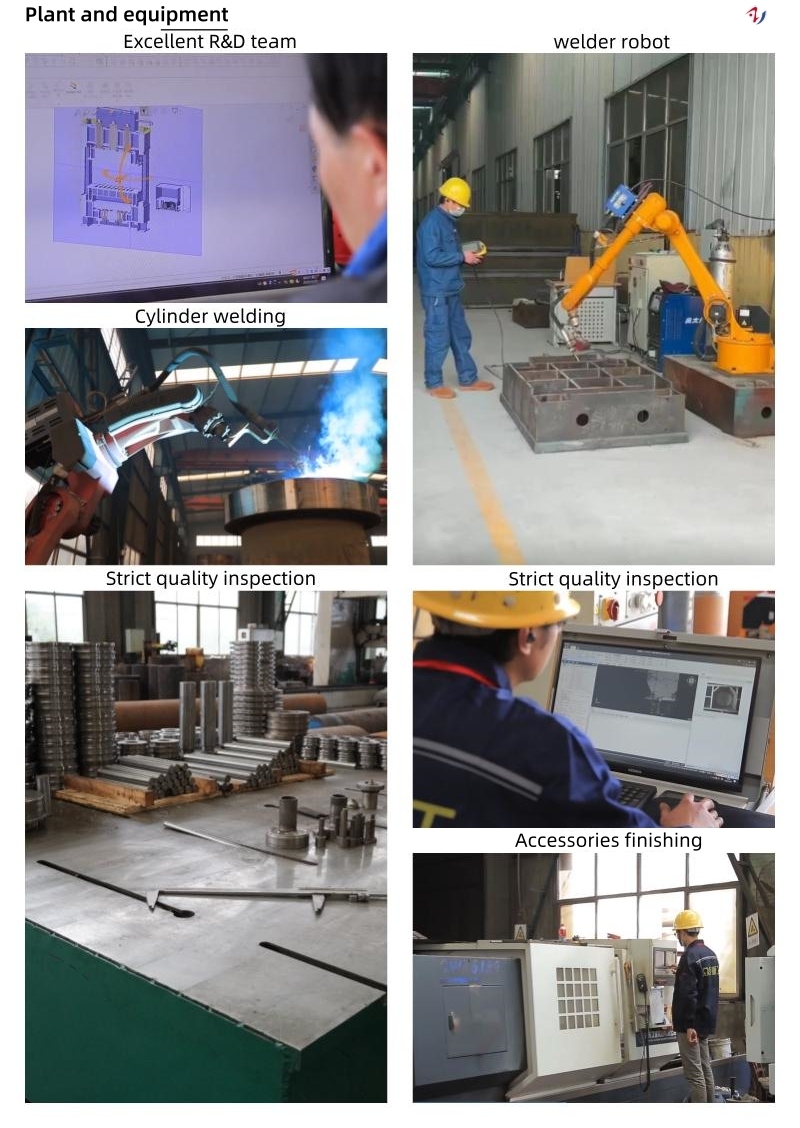

630-ton powder forming hydraulic press: also known as fully automatic salt licking block briquetting machine, it is the core equipment of the production line. It adopts advanced integrated control, has high pressure and high precision, and can press and shape materials into salt bricks. The press has an automatic feeding device and floating pressure function, which can effectively control the molding density of the product; its mechanical stop positioning and stepless adjustment mechanism at three positions of loading, molding, and demoulding can ensure that the geometric dimensions of the product are stable and adjustable; Also equipped with oil cooling device. In addition, presses generally use PLC and human-machine interface centralized control, and are equipped with mechanical limit devices to ensure the consistency of products. Its main features are as follows: The fuselage has a four-beam and four-column structure, with optimized design of stress-bearing parts, beautiful appearance, economical and practical.

Automatic sealing and cutting machine: seals the pressed bricks to protect their shape and quality.

Conveyor belt: used to transport the pressed licking bricks to the next process.

Heat shrinkable tape (if used): Perform heat shrinkage treatment on the packaged licking bricks to improve the tightness and aesthetics of the package.

Automatic sealing and cutting machine: seals the pressed bricks to protect their shape and quality.

Conveyor belt: used to transport the pressed licking bricks to the next process.

Heat shrinkable tEmail: 1959246186@qq.com WhatsApp: +8613562463338ape (if used): Perform heat shrinkage treatment on the packaged licking bricks to improve the tightness and aesthetics of the package.

Email: 1959246186@qq.com

WhatsApp: +8613562463338