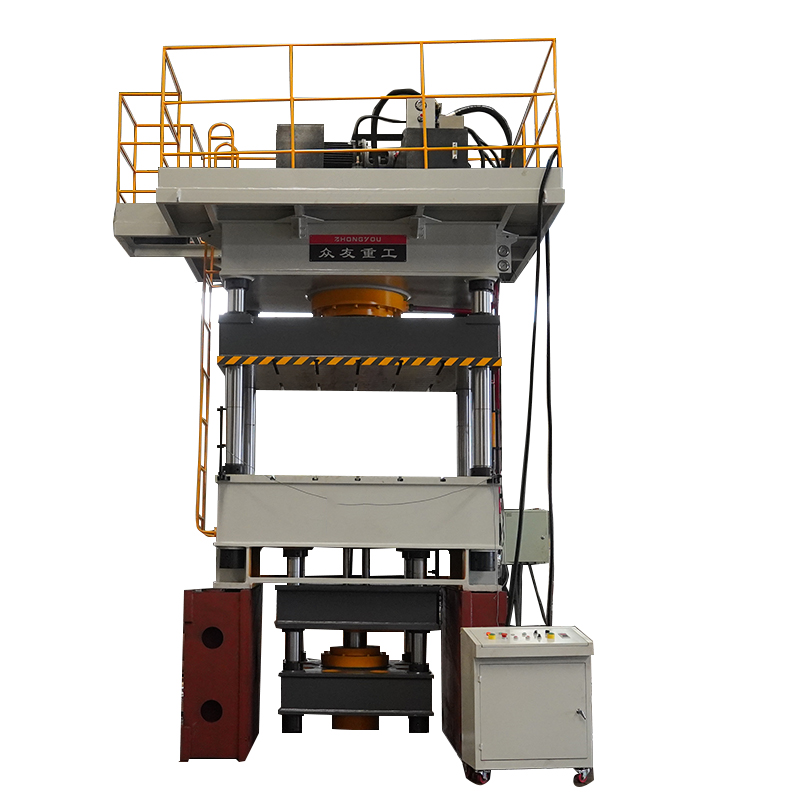

500-ton Hydraulic Press for Flange Bending Deep Drawing Hydraulic Press

The 500-ton head stretching hydraulic press is a four-column hydraulic press whose core function is to apply immense tensile force in conjunction with specific dies to induce plastic deformation in fl

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 500-ton head stretching hydraulic press is a four-column hydraulic press whose core function is to apply immense tensile force in conjunction with specific dies to induce plastic deformation in flat plate blanks—either cold or hot—transforming them into hollow, thin-walled shell heads.High-Rigidity Frame: Typically employs an integral frame structure welded from high-quality steel plates and subjected to stress-relief treatment. This ensures excellent rigidity, minimal deformation, and the ability to withstand significant off-center loads, guaranteeing forming precision and mold longevity.

Precise Hydraulic and Control System: Speed Control: Features multi-stage speeds including slow approach, working stretch, and rapid return, with smooth and adjustable working speeds.

Head forming is suitable for cold and hot forming of heads for pressure vessels such as air tanks, gas cylinders, and gas tanks. It can produce various head types including elliptical, dish-shaped, spherical, and flat-bottomed.

Other processes include drum forming, flanging, and leveling of thick and thin steel plates. Metal shallow drawing and deep drawing (e.g., stainless steel products, cylindrical parts, etc.).

Technical Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Pressing process

Customer Case

Technical Parameters

| YD27 Parameters | Unit | 100T | 200TA | 200TB | 315T | 500T | 630T | 800T | 1000T |

|---|---|---|---|---|---|---|---|---|---|

| Liquid Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Effective Stroke of Slider | mm | 600 | 600 | 700 | 800 | 900 | 900 | 900 | 900 |

| Open Height | mm | 900 | 900 | 1200 | 1250 | 1500 | 1500 | 1500 | 1500 |

| Effective Area of Workbench | mm | 750×700 | 800×800 | 1000×1000 | 1260×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 |

| Free Fall Speed | mm/s | 90 | 100 | 100 | 120 | 120 | 130 | 150 | 150 |

| Pressing Speed | mm/s | 17 | 14 | 14 | 11 | 18 | 18 | 18 | 18 |

| Return Speed | mm/s | 110 | 110 | 110 | 100 | 170 | 180 | 180 | 190 |

| Motor Power | kW | 7.5 | 7.5 | 7.5 | 22 | 37 | 44 | 60 | 74 |

| Hydraulic Pad Ejecting Force | T | 50 | 60 | 60 | 100 | 160 | 200 | 315 | 400 |

| Ejecting Stroke | mm | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| Hydraulic Pad Area | mm | Φ500 | Φ550 | 750×600 | 750×750 | 1050×1050 | 1200×1200 | 1200×1200 | 1200×1200 |

Pressing process

Customer Case