2500 ton facade embossing hydraulic press 2500T anti-theft door embossing hydraulic press

The 2500 ton facade embossing hydraulic press is customized for Zhejiang customers and is a large-scale hydraulic press suitable for facade embossing technology. It is mainly used in the embossing pro

+86 13562463338

+86 13562463338

Video Display

Product Introduction

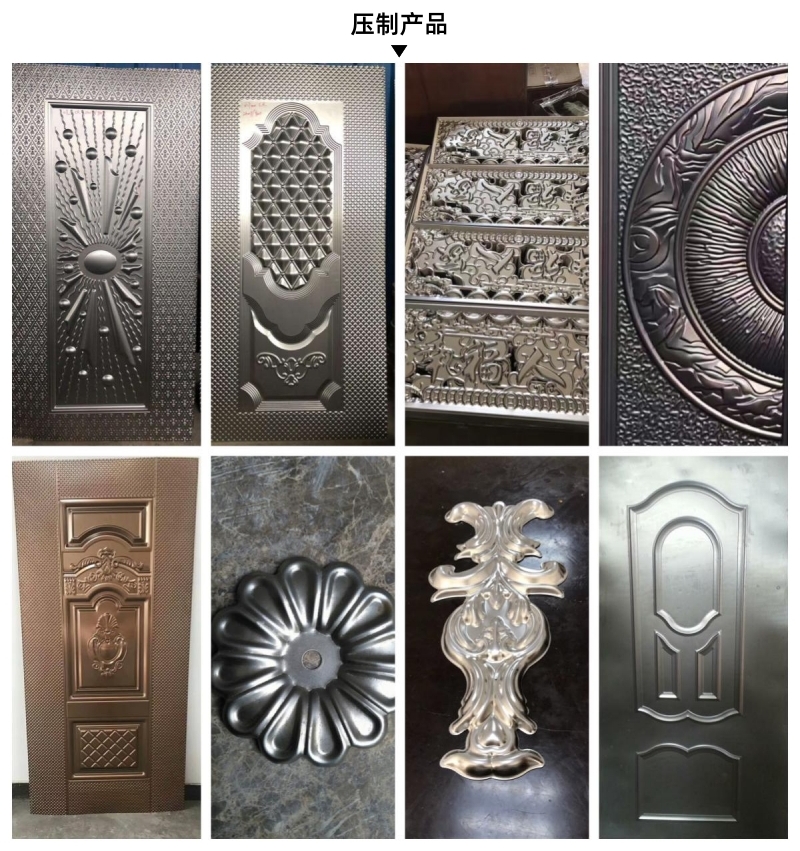

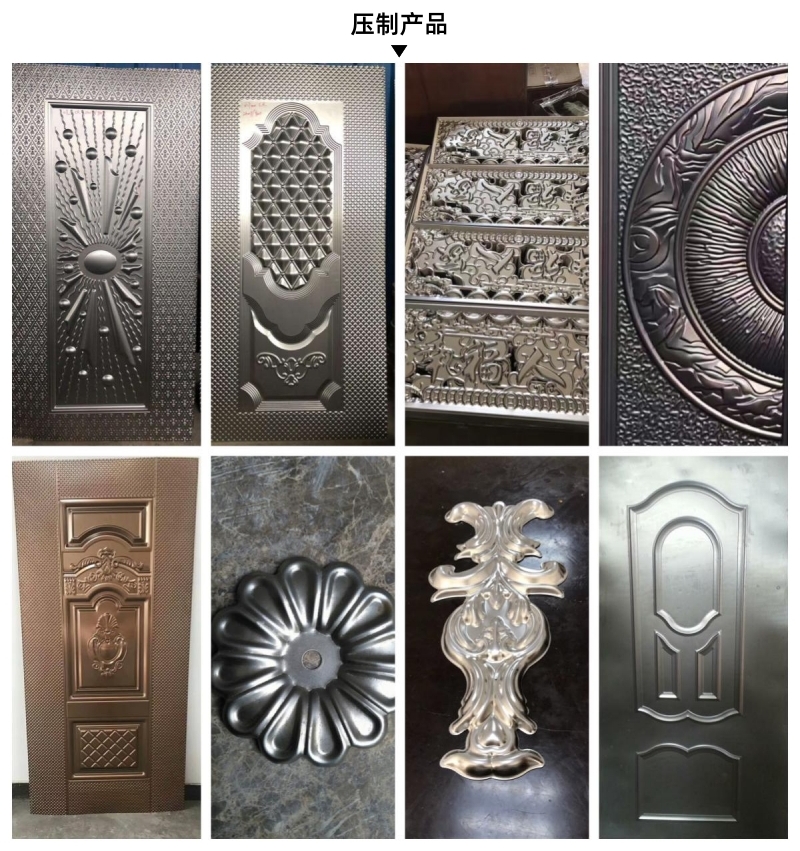

The 2500 ton facade embossing hydraulic press is customized for Zhejiang customers and is a large-scale hydraulic press suitable for facade embossing technology. It is mainly used in the embossing process of steel wooden doors, entrance doors, large iron doors, anti-theft doors, etc. It can press metal iron plates, cold plates, stainless steel plates, aluminum plates and other materials to achieve the effect of facade embossing molding.

Hydraulic presses have a series of significant advantages. Firstly, it has high production accuracy, low energy consumption, smooth operation, and simple operation, which can meet the needs of large-scale production. The structure is simple, economical, and practical. The frame structure has good rigidity, high precision, and strong resistance to eccentric loads, ensuring the stability and accuracy of the work. In addition, the hydraulic control adopts a plug-in foundation system, which is reliable in action, has a long service life, and has low hydraulic impact, reducing the connection of pipelines and leakage points, further improving the reliability and durability of the equipment.

In the facade embossing process, the 2500 ton facade embossing hydraulic press can achieve two forming processes: fixed pressure and fixed stroke, with pressure holding delay function and adjustable delay time. The work pressure and travel can be adjusted within the specified range to meet the needs of different materials and processes. At the same time, it adopts button centralized control and has three operation modes: adjustment, manual, and semi-automatic, making it convenient for users to operate according to specific needs.

The hydraulic press is also equipped with advanced plug-in valves and PLC programmable controllers, achieving independent control of electrical and hydraulic power mechanisms. This design not only improves the automation level of the equipment, but also makes maintenance and debugging of the equipment more convenient and efficient.

| Model | Table Size | Stroke | Opening |

|---|---|---|---|

| YM-1600T | 1500*2200 | 400 | 500 |

| YM-2000T | 1800*2500 | 400 | 500 |

| YM-3000T | 2000*3000 | 400 | 500 |

| YM-3600T | 2100*3200 | 400 | 500 |

| YM-4800T | 2200*3500 | 400 | 500 |

| YM-6000T | 2400*3600 | 400 | 500 |

| YM-8000T | 2600*4000 | 400 | 500 |

| YM-10000T | 2800*4200 | 400 | 500 |

| YM-12000T | 3000*4500 | 400 | 500 |

| Model | Table Size | Stroke | Opening |

|---|---|---|---|

| YM-1600T | 1500*2200 | 400 | 500 |

| YM-2000T | 1800*2500 | 400 | 500 |

| YM-3000T | 2000*3000 | 400 | 500 |

| YM-3600T | 2100*3200 | 400 | 500 |

| YM-4800T | 2200*3500 | 400 | 500 |

| YM-6000T | 2400*3600 | 400 | 500 |

| YM-8000T | 2600*4000 | 400 | 500 |

| YM-10000T | 2800*4200 | 400 | 500 |

| YM-12000T | 3000*4500 | 400 | 500 |