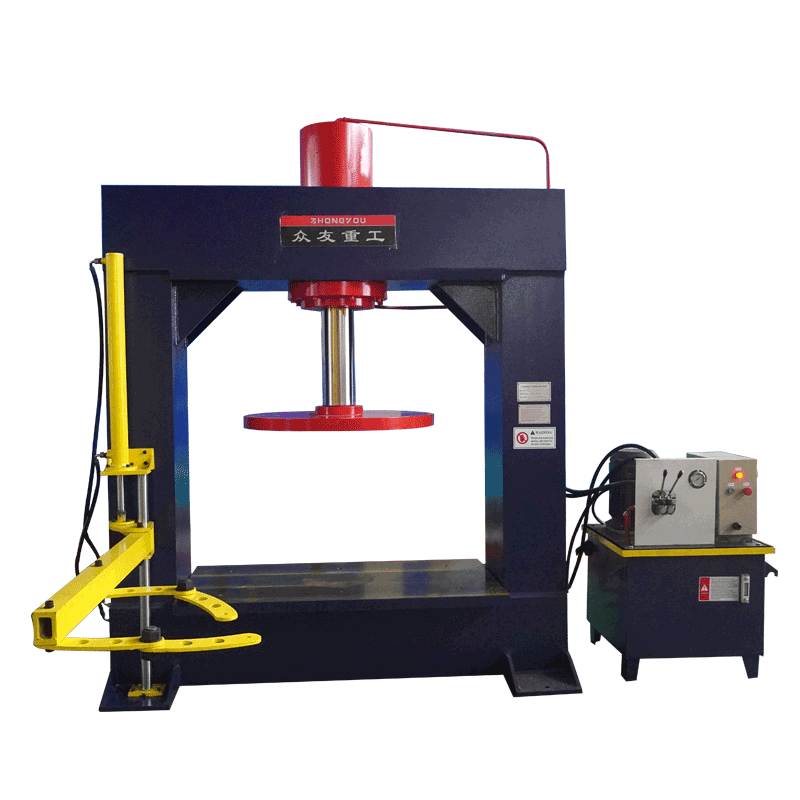

200-Ton Frame Hydraulic Press Automotive Metal Parts Row-Pin Punching Hydraulic Press

The 200-ton frame press features a high-rigidity welded frame structure. Compared to four-column hydraulic presses, it offers significantly enhanced resistance to off-center loading and structural str

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 200-ton frame press features a high-rigidity welded frame structure. Compared to four-column hydraulic presses, it offers significantly enhanced resistance to off-center loading and structural strength, making it ideal for high-precision, high-load punching processes. The machine body comprises an upper crossbeam, movable crossbeam, lower crossbeam, and columns. Guided by flat rails with adjustable clearance, it ensures long-term operational precision.

Ideal for punching metal studs such as iron nails and steel nails, it enables simultaneous punching of multiple holes to boost production efficiency. Applications include stretching and punching operations for automotive exhaust pipe heat shields and stainless steel end caps.

The 200-ton frame-type metal strip nail punching hydraulic press is a critical, high-efficiency specialized equipment in the metal fastener manufacturing industry. It combines traditional hydraulic press pressure with high-precision dies and automated feeding systems, perfectly addressing the mass production and high-quality requirements for multi-hole, regular-shaped parts like "metal strip nails."

Pressing process

Customer Case

Pressing process

Customer Case