VTC650 vertical CNC lathe wheel hub brake drum cutting CNC vertical lathe high-precision vertical lathe

VTC65 brake disc CNC vertical lathe is a high-performance machine tool carefully customized by Shandong Zhongyou Heavy Industry Machinery Co., Ltd. for the specific needs of customers in Zhejiang. Thi

+86 13562463338

+86 13562463338

Video Display

Product Introduction

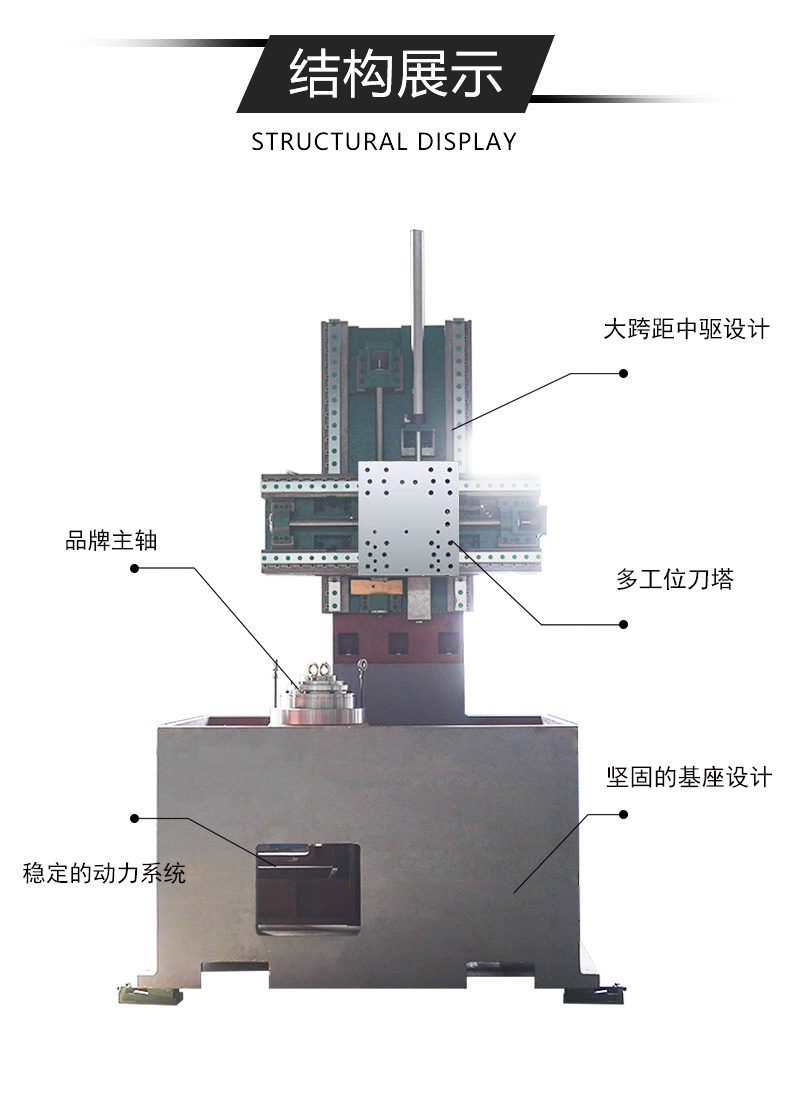

VTC65 brake disc CNC vertical lathe is a high-performance machine tool carefully customized by Shandong Zhongyou Heavy Industry Machinery Co., Ltd. for the specific needs of customers in Zhejiang. This machine tool performs excellently in processing disc and gear parts, especially in handling wire rail hard rail CNC vertical lathes and wheel hub vertical lathes, with significant advantages. The VTC65 CNC vertical lathe has a high-strength cast iron base and columns, ensuring the stability and seismic performance of the machine tool. The design of the vertical structure makes it more convenient to clamp workpieces, while occupying a relatively small area, suitable for use in factories of all sizes.

Processing types: disc type, wheel hub, differential housing, motor housing, oil cylinder, clutch, valve and other different disc type parts。

Application industries: automotive, tractor, engine, motor, construction machinery, gardening machinery, hydraulic machinery and other industries

| Max.rotating diameter | mm | ∮560 | ∮650 | ∮750 | ∮750 | ∮750 |

| Max.turning diameter of workpiece | mm | ∮450 | ∮600 | ∮700 | ∮550 | ∮700 |

| Spindle end face form | Straight | Straight | Straight | Straight | Straight | |

| Spindle speed | rpm | 3000 | 100-1000 | 50-1500 | 50-1000 | 500-1000 |

| Hydraulic chuck diameter | mm | 500 | 500 | 630 | 500 | 630 |

| Tool post type | pcs | eight-station | eight-station | eight-station | eight-station | eight-station |

| Tool shank diameter | mm | 32 | 32 | 32 | 32 | 32 |

| Inner diameter tool holder | mm | ∮40 | ∮40 | ∮50 | ∮50 | |

| Center tool holder | mm | 160 | ||||

| X axis travel | mm | 400 | 450 | 700 | 280 | 450 |

| Z axis travel | mm | 500 | 600 | 700 | 500 | 700 |

| Oil tank capacity | L | 50 | 50 | 50 | 50 | 50 |

| Oil pressure motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Water Capacity | L | 180 | 200 | 200 | 200 | 200 |

| Rotating water motor | w | 250 | 450 | 450 | 450 | 450 |

| Flush motor | kw | 250 | 450 | 450 | 450 | 450 |

| X axis servo motor torque | NM | 12 | 18 | 18 | 15 | 15 |

| Z axis servo motor torque | NM | 22 | 30 | 18 | 15 | 15 |

| Main Servo motor power | kw | 11/15 | 18.5 | 22 | 18.5 | 22 |

| Repeat positioning accuracy | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Positioning accuracy | mm | ±0.008 | ±0.008 | ±0.008 | ±0.008 | ±0.008 |

| Dimension | mm | 1700X1880X2500 | 2000X1950X3000 | 2450X1900X3200 | 3000X2400X2700 | 3200X2400X3200 |

| Weight | kg | 5500 | 8000 | 9500 | 7000 | 9000 |

| Voltage | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | |

| Electricity Leakage/outage protection | √ | √ | √ | √ | √ | |

| Three-color light indication | √ | √ | √ | √ | √ | |

| Long-term stable working conditions | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | |

| Noise meets national standards | √ | √ | √ | √ | √ | |

| ☆The equipment adopts fully enclosed protection, and the protective device is safe and reliable and should comply with GB15760-1995 General Technical Regulations on Safety Protection of Metal Cutting Machine Tools. ☆Equipped with various hydraulic, gas and water pipeline direction signs, marking the working range of various instruments, and marking the grade of the medium used. ☆The diameter of the hydraulic chuck and the tool holder station can be selected according to the processing requirements. | ||||||

| Max.rotating diameter | mm | ∮560 | ∮650 | ∮750 | ∮750 | ∮750 |

| Max.turning diameter of workpiece | mm | ∮450 | ∮600 | ∮700 | ∮550 | ∮700 |

| Spindle end face form | Straight | Straight | Straight | Straight | Straight | |

| Spindle speed | rpm | 3000 | 100-1000 | 50-1500 | 50-1000 | 500-1000 |

| Hydraulic chuck diameter | mm | 500 | 500 | 630 | 500 | 630 |

| Tool post type | pcs | eight-station | eight-station | eight-station | eight-station | eight-station |

| Tool shank diameter | mm | 32 | 32 | 32 | 32 | 32 |

| Inner diameter tool holder | mm | ∮40 | ∮40 | ∮50 | ∮50 | |

| Center tool holder | mm | 160 | ||||

| X axis travel | mm | 400 | 450 | 700 | 280 | 450 |

| Z axis travel | mm | 500 | 600 | 700 | 500 | 700 |

| Oil tank capacity | L | 50 | 50 | 50 | 50 | 50 |

| Oil pressure motor | kw | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Water Capacity | L | 180 | 200 | 200 | 200 | 200 |

| Rotating water motor | w | 250 | 450 | 450 | 450 | 450 |

| Flush motor | kw | 250 | 450 | 450 | 450 | 450 |

| X axis servo motor torque | NM | 12 | 18 | 18 | 15 | 15 |

| Z axis servo motor torque | NM | 22 | 30 | 18 | 15 | 15 |

| Main Servo motor power | kw | 11/15 | 18.5 | 22 | 18.5 | 22 |

| Repeat positioning accuracy | mm | ±0.005 | ±0.005 | ±0.005 | ±0.005 | ±0.005 |

| Positioning accuracy | mm | ±0.008 | ±0.008 | ±0.008 | ±0.008 | ±0.008 |

| Dimension | mm | 1700X1880X2500 | 2000X1950X3000 | 2450X1900X3200 | 3000X2400X2700 | 3200X2400X3200 |

| Weight | kg | 5500 | 8000 | 9500 | 7000 | 9000 |

| Voltage | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | 3¢-AC 380V 50Hz±5% | |

| Electricity Leakage/outage protection | √ | √ | √ | √ | √ | |

| Three-color light indication | √ | √ | √ | √ | √ | |

| Long-term stable working conditions | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | environment Temperature 5~38°, humidity<85% | |

| Noise meets national standards | √ | √ | √ | √ | √ | |

| ☆The equipment adopts fully enclosed protection, and the protective device is safe and reliable and should comply with GB15760-1995 General Technical Regulations on Safety Protection of Metal Cutting Machine Tools. ☆Equipped with various hydraulic, gas and water pipeline direction signs, marking the working range of various instruments, and marking the grade of the medium used. ☆The diameter of the hydraulic chuck and the tool holder station can be selected according to the processing requirements. | ||||||