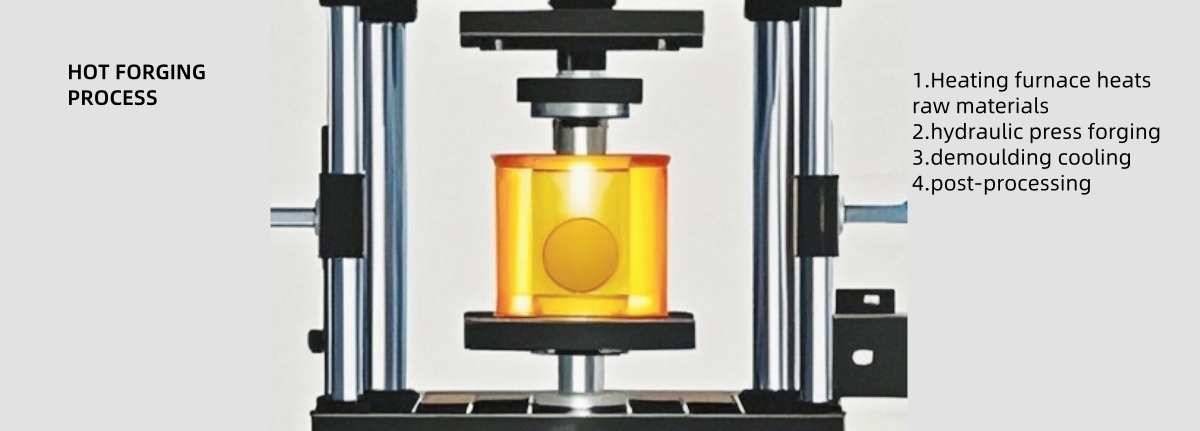

400 tons hot forging frame hydraulic press Red punch die forging press

Hot forging frame hydraulic press is a forging process technology that uses molds to heat and plastically form metal blanks into the required shape and size of forgings. It is mainly used in automobil

+86 13562463338

+86 13562463338

Video Display

Product Introduction

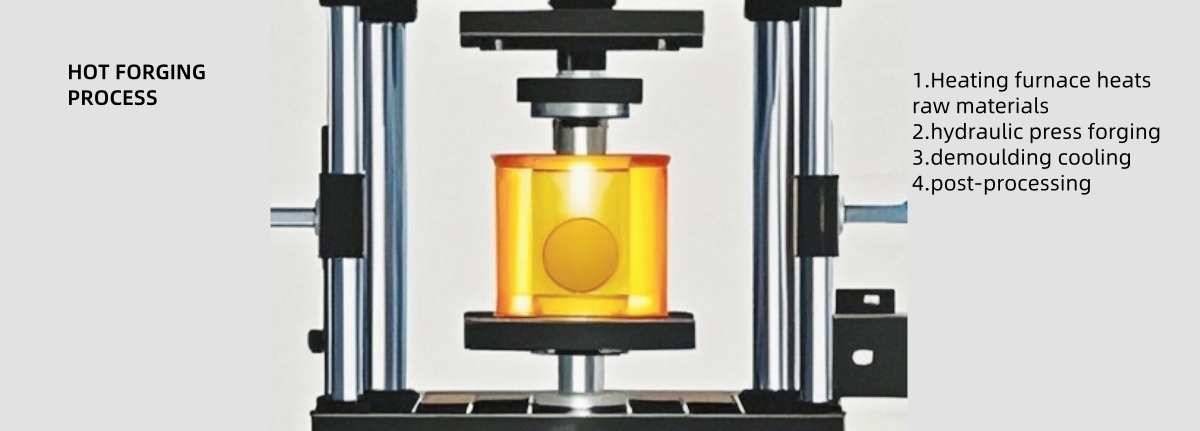

Hot forging frame hydraulic press is a forging process technology that uses molds to heat and plastically form metal blanks into the required shape and size of forgings. It is mainly used in automobiles, tractors, internal combustion engines, ships, aviation, mining machinery, petroleum machinery, hardware tools, etc.

In the manufacturing industry, batches of die forgings and finishing forgings of ferrous and non-ferrous metals are carried out. The fuselage adopts finite element structural analysis and optimized design, and is controlled by PLC.

It can be used for the production of automobile universal joint fork forgings, as well as automobile panel stretching, auto parts molding, and auto parts hot forging; used to manufacture high-precision, high-strength Aerospace parts; used to manufacture key parts in mining equipment, such as shafts, gears, etc.; can also be used for the forging of excavator bucket teeth and chains, camshafts, high-strength bolts, nuts, and other products Molding process.

Pressing process

The frame-type press forming hydraulic press is suitable for imprinting, forming, shallow stretching, shaping, overmolding and trimming of metal or non-metal parts: typical products that can be pressed include watch cases, watch straps, glasses frames and parts, photo frames, Tableware, signs, locks, hardware parts, etc.

Pressing process

The frame-type press forming hydraulic press is suitable for imprinting, forming, shallow stretching, shaping, overmolding and trimming of metal or non-metal parts: typical products that can be pressed include watch cases, watch straps, glasses frames and parts, photo frames, Tableware, signs, locks, hardware parts, etc.