315t powder forming cattle and sheep licking brick hydraulic press 315t salt brick briquetting press

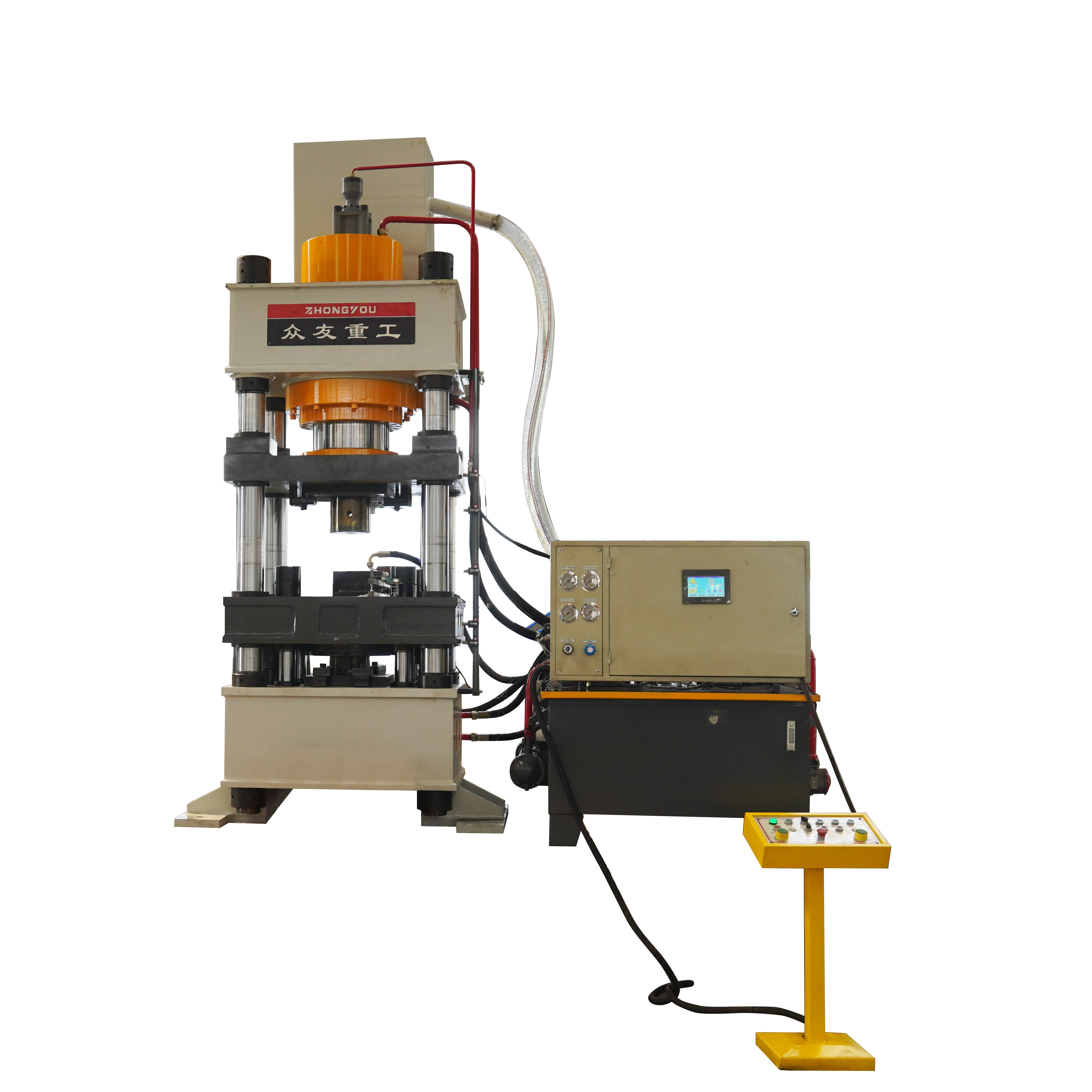

The 315-ton powder forming hydraulic press for cattle and sheep bricks is a device used to press cattle and sheep licking bricks. It usually adopts a four-beam and four-column structure, which has the

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 315-ton powder forming hydraulic press for cattle and sheep bricks is a device used to press cattle and sheep licking bricks. It usually adopts a four-beam and four-column structure, which has the advantages of high reliability, high precision, fast pressing speed, high production efficiency, and energy saving.

The whole machine has been designed through finite element optimization and industrial design. It is appropriate to pay attention to the overall performance, practicality, durability, high stiffness and high reliability of the whole machine. At the same time, attention should also be paid to the humanized design style of the shape and color of the whole machine.

Performance features include:

It adopts PLC hydraulic transmission system, which is powerful and controllable, and can improve the output and quality of products.

Using hydraulic components, it can achieve continuous normal operation. It can produce various styles of product shapes with different molds. One machine has high multi-purpose performance.

It has an independent power mechanism and electrical control system, which is simple and convenient to operate. It can reduce the failure rate of the machine to a certain extent. The fully automated productivity can increase the economic benefits of the user.

It can be equipped with rapid equipment to speed up production and increase product output.

By changing the mold, various styles of products can be produced to realize the dance of the product.

The 315-ton salt brick hydraulic press is mainly evaluated in the field of animal husbandry and is used to produce feed supplements such as cattle and sheep licking bricks. Licking bricks supplements a variety of trace elements and surpluses needed by cattle and sheep, and plays an important role in improving the health and production performance of cattle and sheep.

Email: 1959246186@qq.com

WhatsApp: +8613562463338

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |