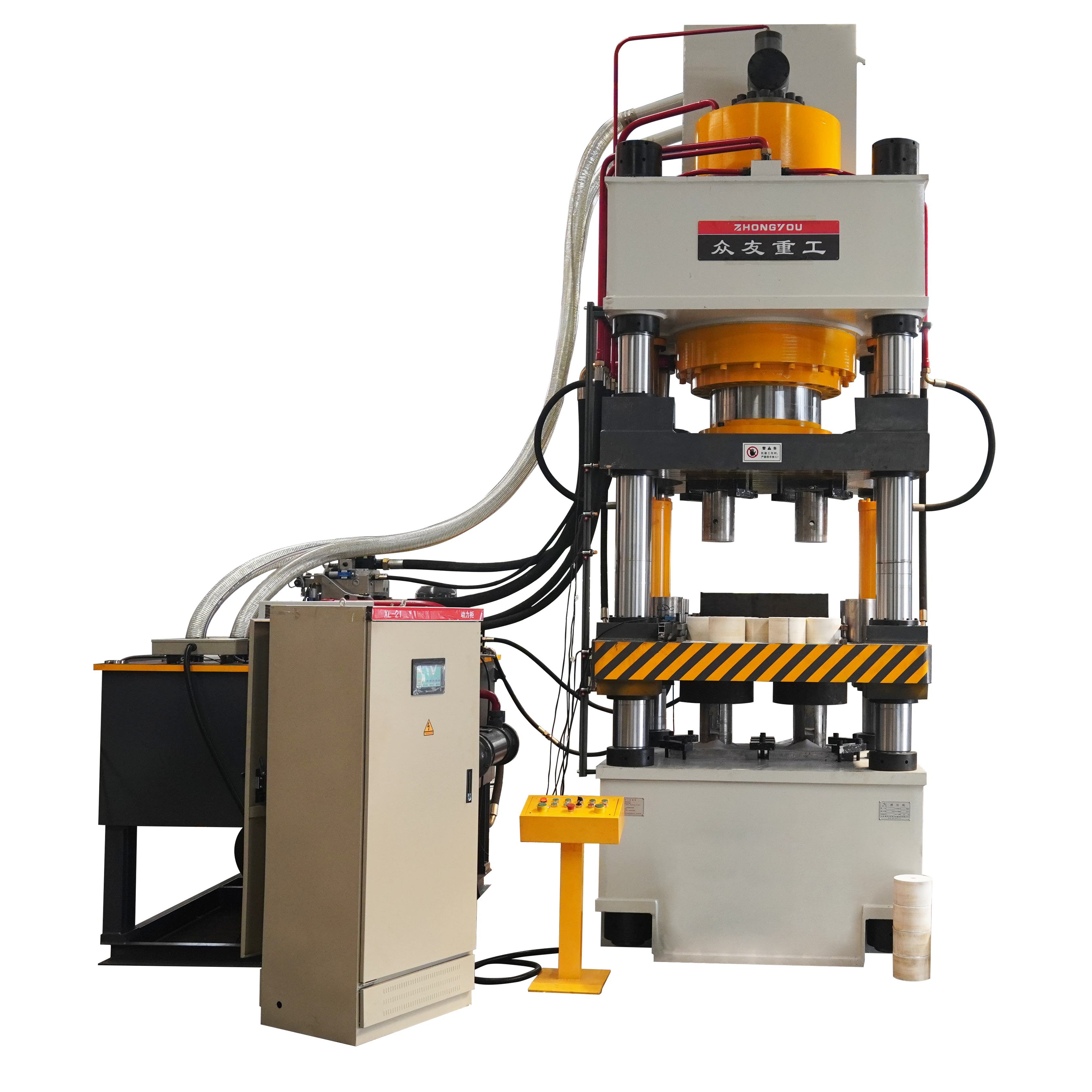

800T Salt Brick Machine Production Line 800T Cattle and Sheep Brick Licking Hydraulic Press Manufacturer

The 800-ton cattle and sheep licking brick hydraulic press production line is an automated production line specially used to produce cattle and sheep licking bricks.The production line mainly consists

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 800-ton cattle and sheep licking brick hydraulic press production line is an automated production line specially used to produce cattle and sheep licking bricks.

The production line mainly consists of the following parts:

Blender: Used to mix the raw materials evenly to ensure that the ingredients of the licking bricks are consistent.

Material lifting pipe: transport the mixed raw materials to the storage bin or directly to the host machine.

Storage silo: temporarily stores mixed raw materials for continuous production.

Host machine (hydraulic press): The 800-ton hydraulic press is the core equipment of the production line and is used to press raw materials into shape. The hydraulic press has strong pressure to ensure the density and hardness of the licked bricks.

Automatic sealing and cutting machine: After the bricks are formed, they are automatically cut and sealed to improve production efficiency.

Conveyor belt: used to transport finished bricks to the next process or packaging area.

Heat shrinkable tape (if any): Perform heat shrinkage treatment on the packaged licking bricks to improve the sealing and aesthetics of the packaging.

The production line also has a complete automated control system, which can accurately control the entire production process, such as pressure, pressing time, temperature and other parameters, to ensure the stability and consistency of the quality of each batch of licked bricks.

Email: 1959246186@qq.com

WhatsApp: +8613562463338

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |