120 ton tire press with hydraulic lift table

The 120-ton solid tire disassembly and assembly hydraulic press, also known as the 120-ton gantry tire press or solid tire press, is a piece of equipment specially used for disassembly and assembly of

+86 13562463338

+86 13562463338

Video Display

Product Introduction

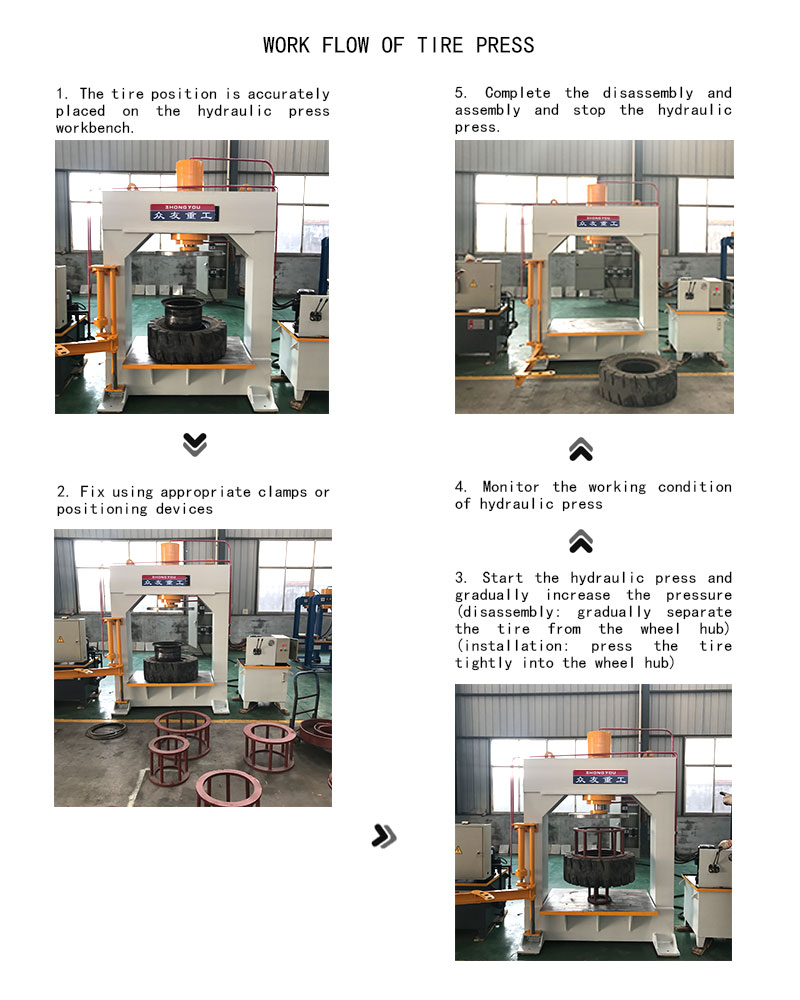

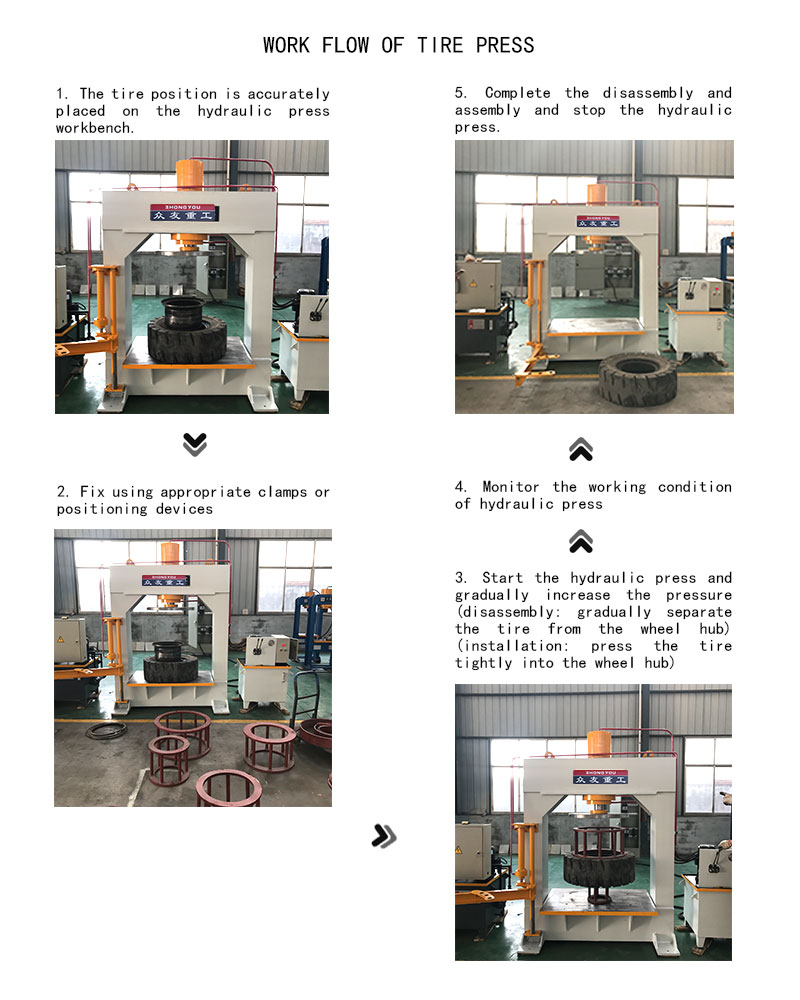

The 120-ton solid tire disassembly and assembly hydraulic press, also known as the 120-ton gantry tire press or solid tire press, is a piece of equipment specially used for disassembly and assembly of solid tires such as large engineering vehicles and forklifts; it uses hydraulic principles to generate powerful pressure to achieve quick and safe disassembly and assembly of tires.

The 120-ton solid tire disassembly and assembly hydraulic press, also known as the 120-ton gantry tire press or solid tire press, is a piece of equipment specially used for disassembly and assembly of solid tires such as large engineering vehicles and forklifts; it uses hydraulic principles to generate powerful pressure to achieve quick and safe disassembly and assembly of tires.

Features

Efficiency: It can quickly complete the disassembly and assembly of tires and improve work efficiency.

Safety: It can protect the tires and rims from damage during disassembly and assembly, ensuring the reusability of the tires.

Wide applicability: Suitable for disassembly and assembly of solid tires on various large engineering vehicles, forklifts, etc.

Easy to operate: It adopts hydraulic control system, which is easy to operate and easy to use.

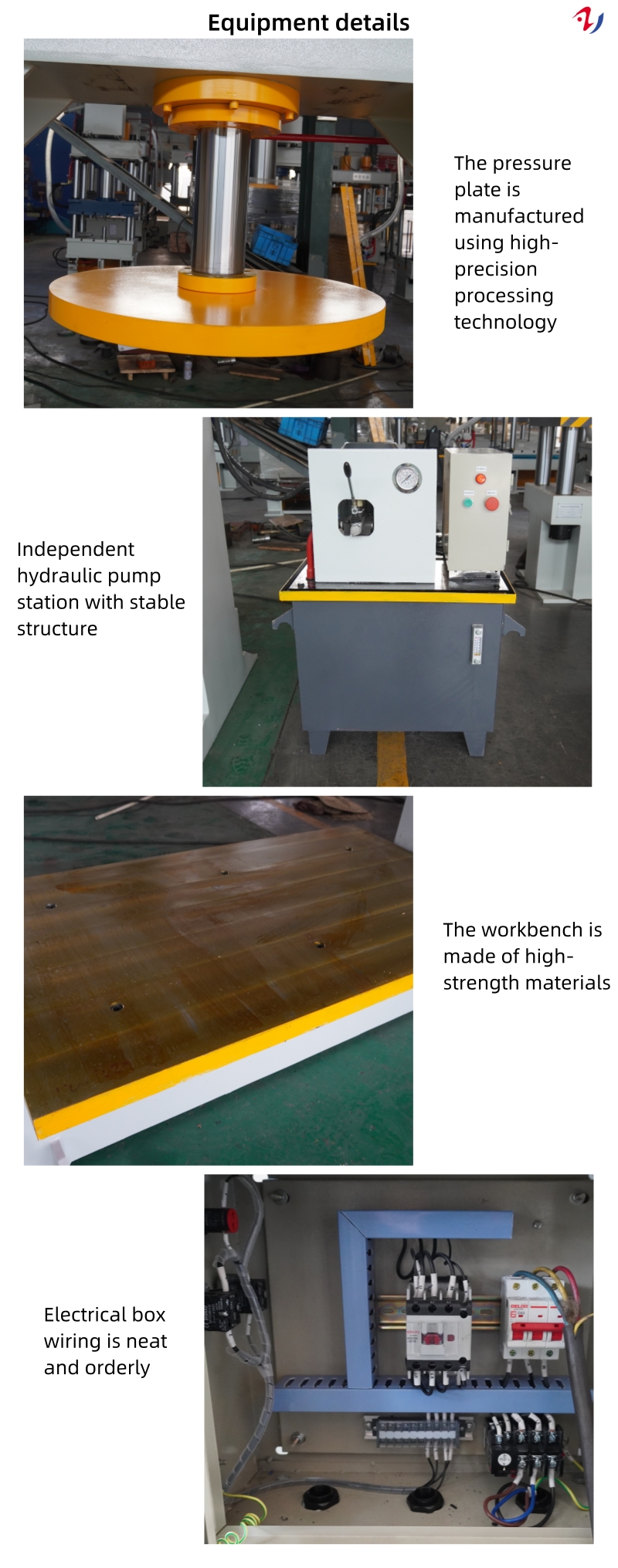

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000x800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000x800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400x800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500x800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500x800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500x800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| Tonnage | Working Pressure | Cylinder Diameter/Rod Diameter | Effective Table Size | Opening Height | Stroke | Pressing Speed | Return Speed | Motor Power | Oil Pump Specification |

|---|---|---|---|---|---|---|---|---|---|

| 100 | 31.5 | D200/d100 | 1000x800 | 1100 | 500 | 7mm/s | 10mm/s | 5.5kw | 10McY (fixed) |

| 120 | 31.5 | D220/d110 | 1000x800 | 1100 | 600 | 6mm/s | 8mm/s | 5.5kw | 10McY (fixed) |

| 160 | 31.5 | D250/d150 | 1400x800 | 1100 | 600 | 6-12mm/s | 15mm/s | 5.5kw | 25McY (fixed) |

| 200 | 31.5 | D290/d160 | 1500x800 | 1200 | 600 | 4-9mm/s | 12mm/s | 5.5kw | 25McY (fixed) |

| 250 | 31.5 | D310/d180 | 1500x800 | 1200 | 600 | 6-12mm/s | 15mm/s | 7.5kw | 40McY (fixed) |

| 300 | 31.5 | D360/d220 | 1500x800 | 1200 | 600 | 4-9mm/s | 15mm/s | 7.5kw | 40McY (fixed) |