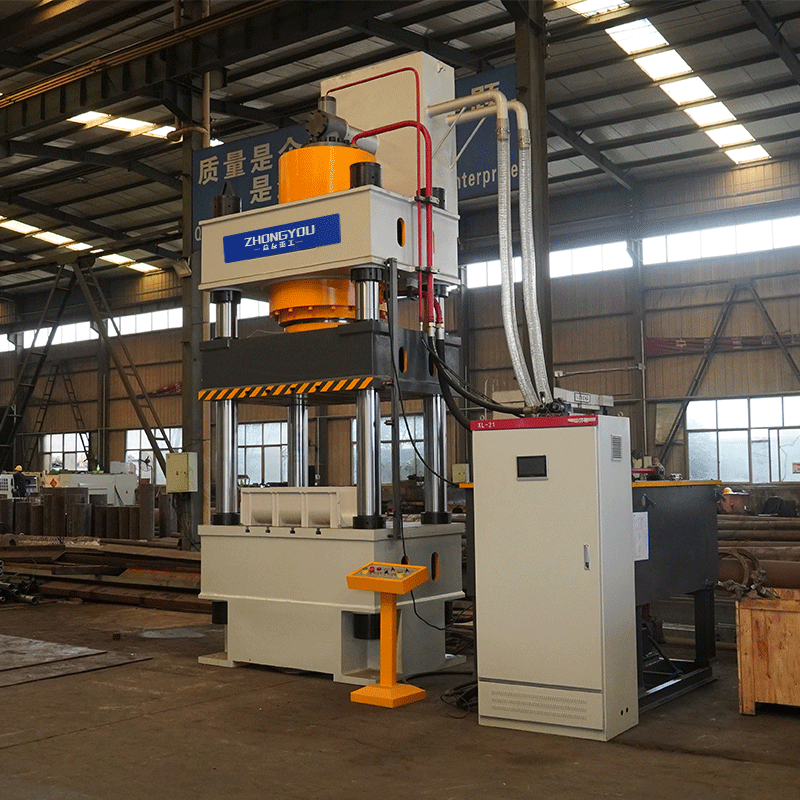

100-ton hydraulic press

The 100-ton hydraulic press is a machine tool integrating hydraulic transmission with stamping capabilities, widely used in sheet metal blanking, bending, flanging, drawing, and cold extrusion of meta

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 100-ton hydraulic press is a machine tool integrating hydraulic transmission with stamping

capabilities, widely used in sheet metal blanking, bending, flanging, drawing, and cold extrusion

of metal parts.

High precision and flexible processing are achieved through a rectangular six-sided guide rail and

slide design, ensuring high guiding accuracy and stability, making it suitable for high-precision

product manufacturing.

Intelligent control employs PLC centralized control with full touchscreen operation, enabling

real-time

display and adjustment of parameters including stroke, speed, time, and pressure.

Application Scenarios

Metal Processing

Aluminum extrusion (e.g., watch cases, watch bands, eyeglass frames), automotive components,

hardware parts, locks, tableware, etc.

Thin Sheet Drawing and Forming

(e.g., metal casings for motors and electrical appliances, lighting fixture components).

Non-Metal Processing: Plastic and powder product compression molding.

Special Processes: Grinding wheel forming, press-fit alignment, tube punching (e.g., copper,

aluminum, steel, stainless steel tubes).

Technical Parameters

| Technical ParametersMain Technical Parameters | Unit | YC21-63T | YC21-80T | YC21-100T | YC21-125T | YC21-160T | YC21-200T | YC21-315T |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | KN | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 3150 |

| Maximum Pressure of Hydraulic System | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Opening Height | mm | 400 | 500 | 500 | 500 | 600 | 600 | 700 |

| Effective Stroke | mm | 200 | 200 | 260 | 260 | 260 | 300 | 300 |

| Effective Area of Workbench (Left-Right) | mm | 700 | 800 | 1000 | 1000 | 1100 | 1100 | 1200 |

| Effective Area of Workbench (Front-Back) | mm | 450 | 480 | 600 | 600 | 700 | 700 | 800 |

| Throat Depth | mm | 220 | 250 | 310 | 310 | 360 | 360 | 410 |

| Slider Dimensions (Left-Right x Front-Back) | mm | 400*300 | 450*330 | 480*360 | 550*400 | 590*440 | 650*480 | 750*570 |

| Workbench Punching Hole Diameter | mm | 150 | 180 | 180 | 180 | 200 | 260 | 260 |

| Motor | KW | 7.5 | 11 | 11 | 15 | 18.5 | 18.5 | 30 |

Pressing process

Customer Case

Technical Parameters

| Technical ParametersMain Technical Parameters | Unit | YC21-63T | YC21-80T | YC21-100T | YC21-125T | YC21-160T | YC21-200T | YC21-315T |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | KN | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 3150 |

| Maximum Pressure of Hydraulic System | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Opening Height | mm | 400 | 500 | 500 | 500 | 600 | 600 | 700 |

| Effective Stroke | mm | 200 | 200 | 260 | 260 | 260 | 300 | 300 |

| Effective Area of Workbench (Left-Right) | mm | 700 | 800 | 1000 | 1000 | 1100 | 1100 | 1200 |

| Effective Area of Workbench (Front-Back) | mm | 450 | 480 | 600 | 600 | 700 | 700 | 800 |

| Throat Depth | mm | 220 | 250 | 310 | 310 | 360 | 360 | 410 |

| Slider Dimensions (Left-Right x Front-Back) | mm | 400*300 | 450*330 | 480*360 | 550*400 | 590*440 | 650*480 | 750*570 |

| Workbench Punching Hole Diameter | mm | 150 | 180 | 180 | 180 | 200 | 260 | 260 |

| Motor | KW | 7.5 | 11 | 11 | 15 | 18.5 | 18.5 | 30 |

Pressing process

Customer Case