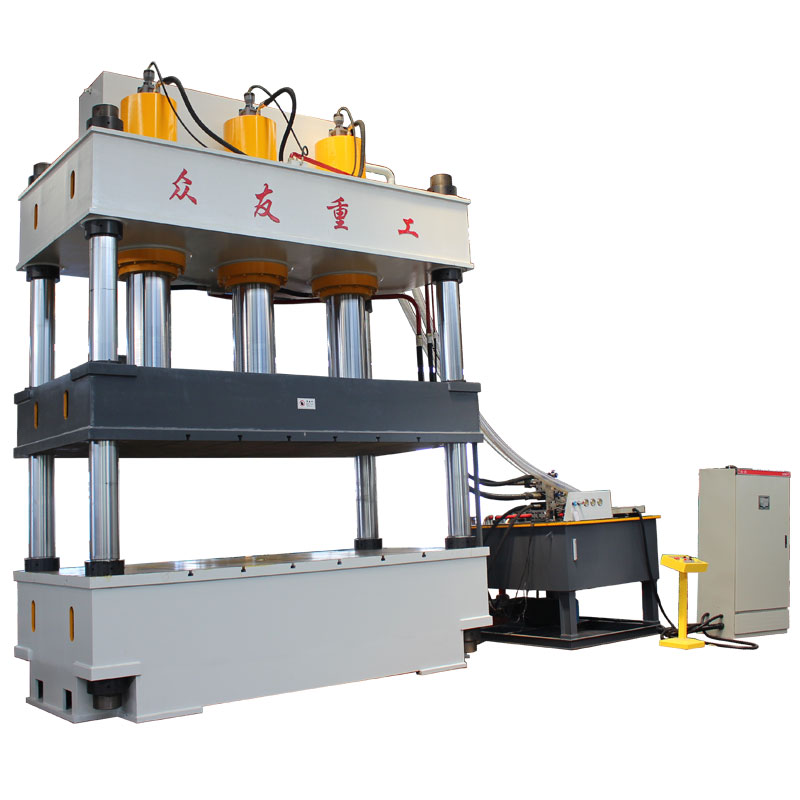

200 tons frame type metal stamping hydraulic press

The 200-ton frame hydraulic press is a large-tonnage hydraulic molding equipment, mainly used for metal, plastic, powder metallurgy and other materials pressure processing, its core features are stron

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 200-ton frame hydraulic press is a large-tonnage hydraulic molding equipment, mainly used for metal, plastic, powder metallurgy and other materials pressure processing, its core features are strong structural rigidity, stable pressure, suitable for scenes that require high tonnage molding.

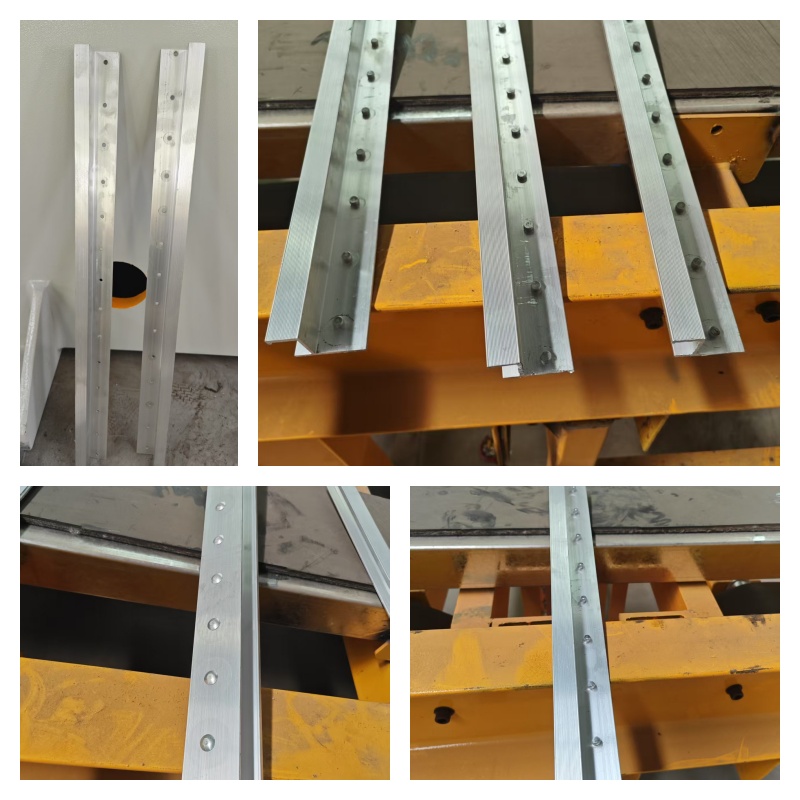

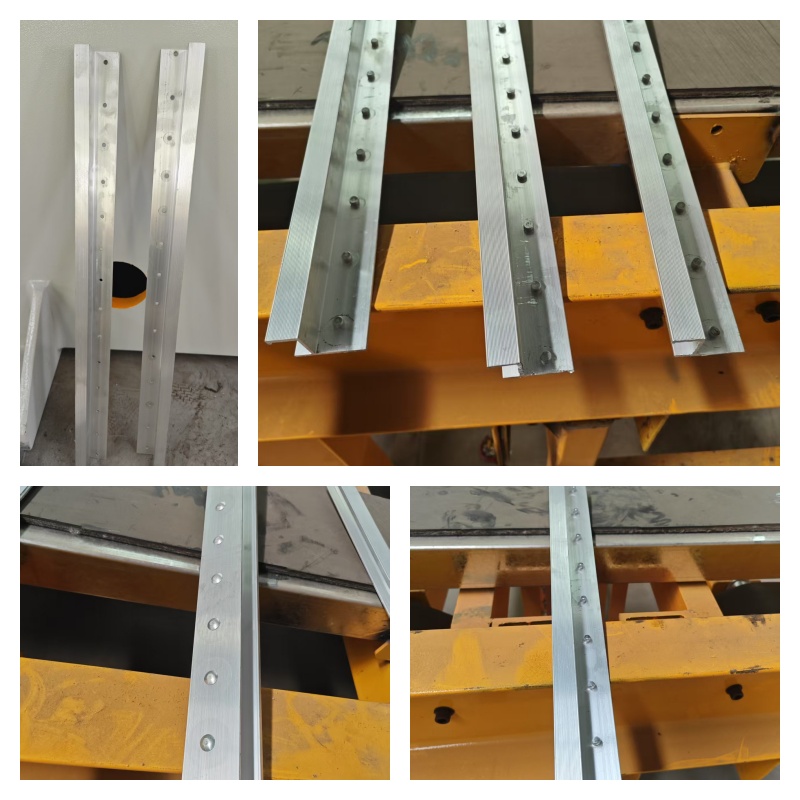

Refrigerated truck sheet metal punching hydraulic press is a special hydraulic equipment designed for punching sheet metal parts of refrigerated truck compartments (e.g. side panels, roof panels, bottom panels, door panels, etc.), whose core demand is to meet the multi-specification hole patterns (round holes, square holes, shaped holes, etc.) of the sheet metal parts, and batch and efficient production, taking into account the accuracy and stability at the same time.

Core components:

Frame: the main structure, determining the rigidity and stability of the equipment (200-ton level is mostly an integral cast steel or reinforced welded frame);

Hydraulic system: including the main cylinder (generating 200 tons of pressure), oil pumps, valves (such as relief valves, directional valves), tanks and pipelines;

Power system: usually motor-driven oil pump (common 380V/50Hz power supply);

Control system: PLC + touch screen (modern equipment) or relay control to realize pressure, stroke and speed adjustment;

Working parts: upper slide (mounting molds), table (to place the workpiece), guide device (to ensure the accuracy of the vertical movement of the slide).

Core Advantages

High rigidity and stability: the frame-type structure (especially the overall cast steel structure) has strong resistance to deformation, which is suitable for precision molding under large tonnage;

Precise and controllable pressure: through the hydraulic valve group and PLC control, it can realize the functions of constant-pressure pressing and holding pressure to ensure the consistency of the workpiece;

Flexibility of process: it can be matched with different molds to achieve a variety of processes such as stamping, stretching, straightening and powder pressing;

High degree of automation: optional photoelectric protection, automatic feeding, counting and other functions to enhance production efficiency;

Convenient maintenance: modular design, hydraulic system and electrical components are easy to overhaul.

200 tons frame hydraulic press is the core equipment of large tonnage forming, with high rigidity, high precision and process flexibility, widely used in metal processing, automotive, aviation and other fields.

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |

| Parameter | Unit | YQ32-63 | YQ32-100A | YQ32-100B | YQ32-200A | YQ32-200B | YQ32-315A | YQ32-315B |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 630 | 1000 | 1000 | 2000 | 2000 | 3150 | 3150 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 700 | 800 | 900 | 1100 | 900 | 1250 | 1000 |

| Maximum Stroke of Slider | mm | 400 | 500 | 600 | 500 | 600 | 800 | 600 |

| Effective Area of Workbench | mm | 610×500 | 630×550 | 750×700 | 1000×1000 | 800×800 | 1260×1160 | 800×800 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Pressing Speed | mm/s | 11-22 | 7-15 | 7-15 | 7-18 | 7-18 | 7-12 | 7-12 |

| Return Speed | mm/s | 80 | 90 | 90 | 90 | 90 | 100 | 90 |

| Ejecting Force | kN | 100 | 200 | 200 | 400 | 400 | 630 | 630 |

| Maximum Ejecting Stroke | mm | 160 | 200 | 200 | 200 | 200 | 300 | 300 |

| Name | Unit | YQ32-400 | YQ32-500 | YQ32-630 | YQ32-800 | YQ32-1000 | YQ32-1250 | YQ32-1600 |

|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 4000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 |

| Maximum System Working Pressure | MPa | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Maximum Open Height of Slider | mm | 1250 | 1500 | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Stroke of Slider | mm | 800 | 900 | 900 | 900 | 900 | 900 | 900 |

| Effective Area of Workbench | mm | 1250×1160 | 1400×1400 | 1500×1500 | 1600×1600 | 1600×1600 | 1600×1600 | 1600×1600 |

| Slider Free Fall Speed | mm/s | 100 | 100 | 150 | 100 | 180 | 180 | 190 |

| Pressing Speed | mm/s | 5-11 | 10-18 | 9-18 | 7-18 | 10-18 | 6-15 | 6-14 |

| Return Speed | mm/s | 100 | 180 | 200 | 90 | 220 | 200 | 220 |

| Ejecting Force | kN | 630 | 1000 | 1000 | 400 | 1000 | 1000 | 1600 |

| Maximum Ejecting Stroke | mm | 300 | 300 | 300 | 200 | 300 | 300 | 300 |