Container Side Plate Press 630 tons frame hydraulic presses

The 630-ton frame hydraulic press is a kind of heavy-duty equipment widely used in metal processing, composite material molding and other fields, and its core features lie in high pressure output, sta

+86 13562463338

+86 13562463338

Video Display

Product Introduction

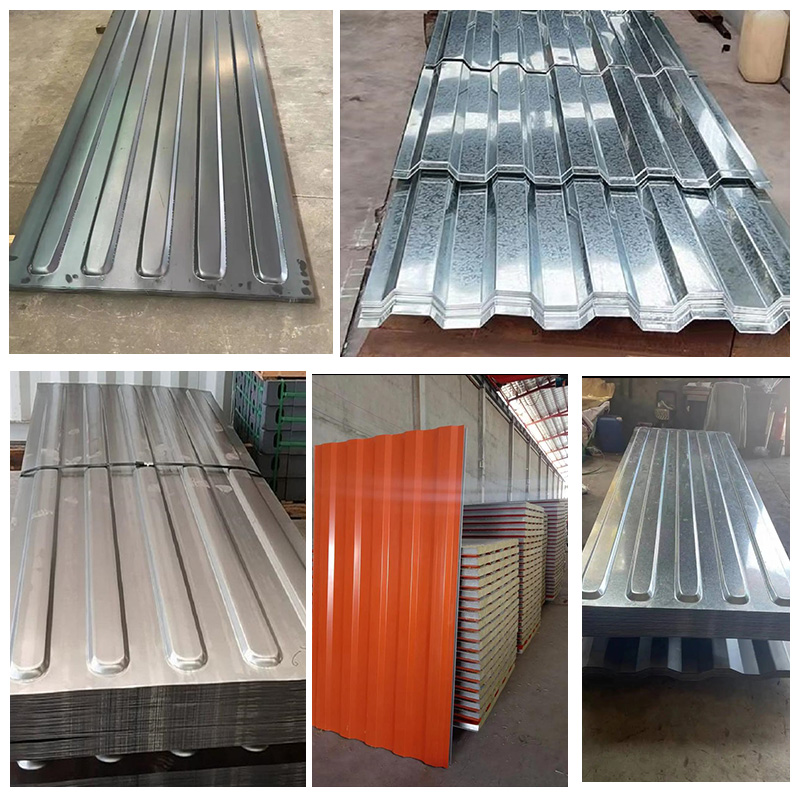

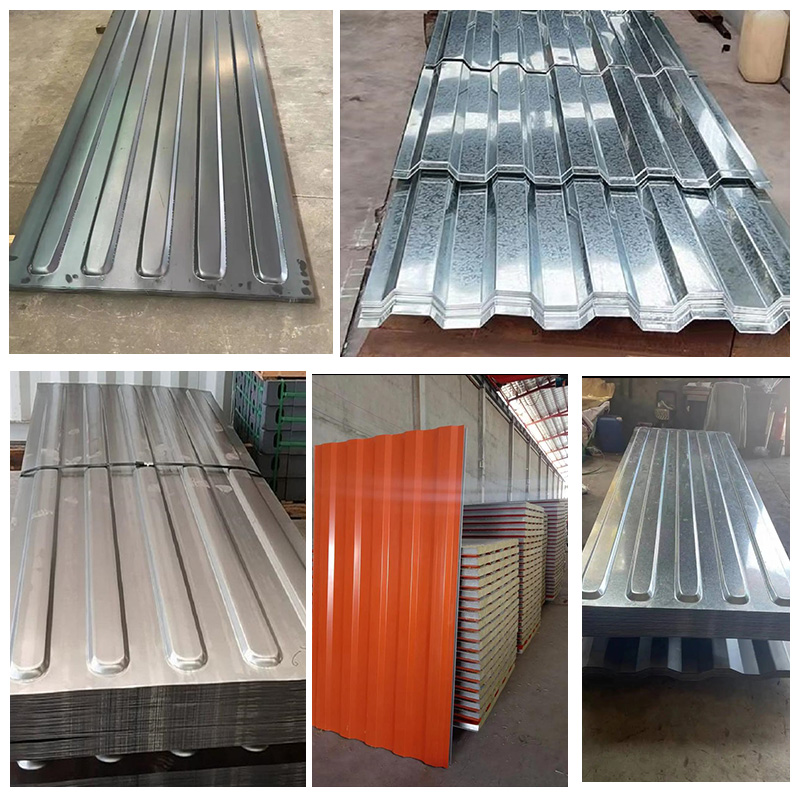

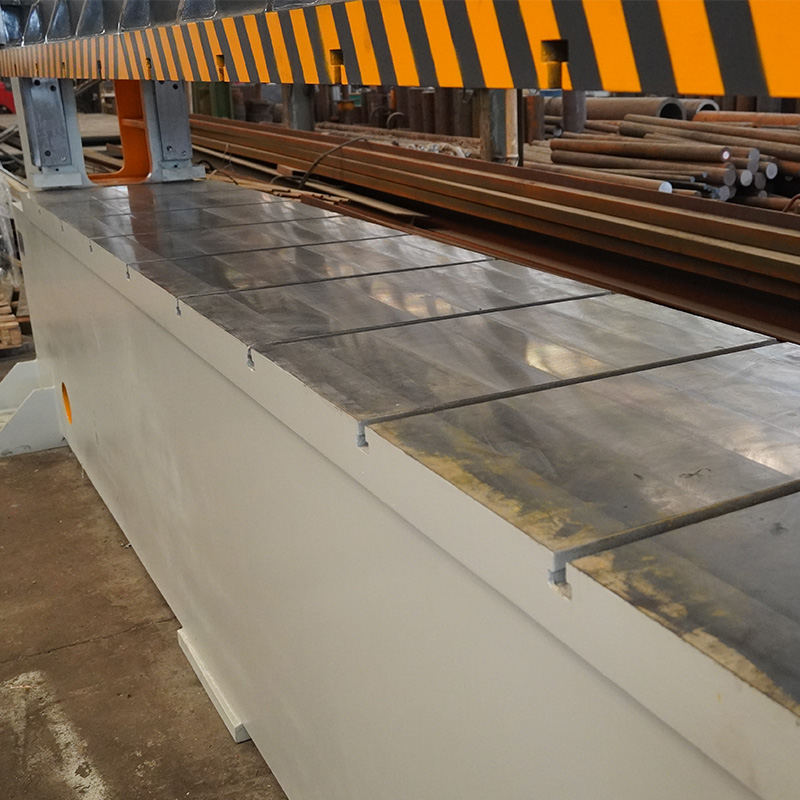

The 630-ton frame hydraulic press is a kind of heavy-duty equipment widely used in metal processing, composite material molding and other fields, and its core features lie in high pressure output, stable structure design and flexible process adaptability.This hydraulic press is used for producing container top plate, side plate, box cargo plate and other reinforced metal plate shaping equipment.

Structural design and technical advantages

Full steel plate welding frame: computer optimized design ensures high rigidity and anti-bias load capacity, and is not easy to be deformed in long-term use.

Four corners and eight surfaces guide rail: high guiding precision, strong resistance to partial load, suitable for high-precision molding process.

Dual-action function: the upper ram and the lower hydraulic pad can be controlled independently, and the ejector force of the hydraulic pad can be up to 2500kN, which is suitable for composite processes such as stretching, bending and punching.

Safety protection: standard equipped with two-hand buttons, safety light curtains, slider safety pins and other devices to ensure the safety of operators.

Typical application scenarios

Metal processing: automotive parts: such as engine block, chassis structural parts of the stretching and molding.

Home appliance manufacturing: stamping and shaping of refrigerator shells and washing machine inner tubes.

Construction building materials: bending and straightening of metal plates and molding of composite materials.

New material molding: powder metallurgy: pressing and sintering of high-density parts.

Carbon fiber composites: molding of prepreg.

Special Processes: Mining Anchor Tray Molding: High precision stamping by customized molds.

Graphene material molding: servo control system ensures precise matching of pressure and temperature.