800 tons cattle and sheep brick licking hydraulic press production line

The 800-ton hydraulic press production line for cattle and sheep licking bricks is an advanced equipment combination specially used for the production of cattle and sheep licking bricks.Mixer: Used to

+86 13562463338

+86 13562463338

Video Display

Product Introduction

The 800-ton hydraulic press production line for cattle and sheep licking bricks is an advanced equipment combination specially used for the production of cattle and sheep licking bricks.

Mixer: Used to mix the raw materials thoroughly and evenly to ensure that the ingredients of the licking bricks are consistent.

Material lifting pipe: transports the mixed raw materials to the storage bin or main machine to improve production efficiency.

Storage silo: stores raw materials to be processed to ensure the continuity of the production process. The material of the storage bin and the material lifting pipe can be selected from stainless steel or carbon steel according to needs.

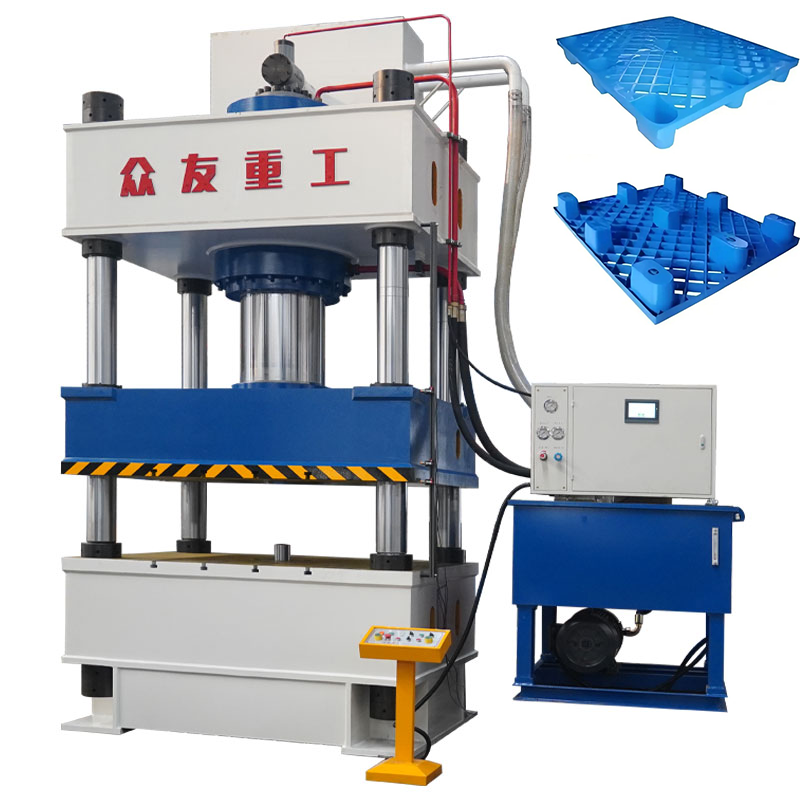

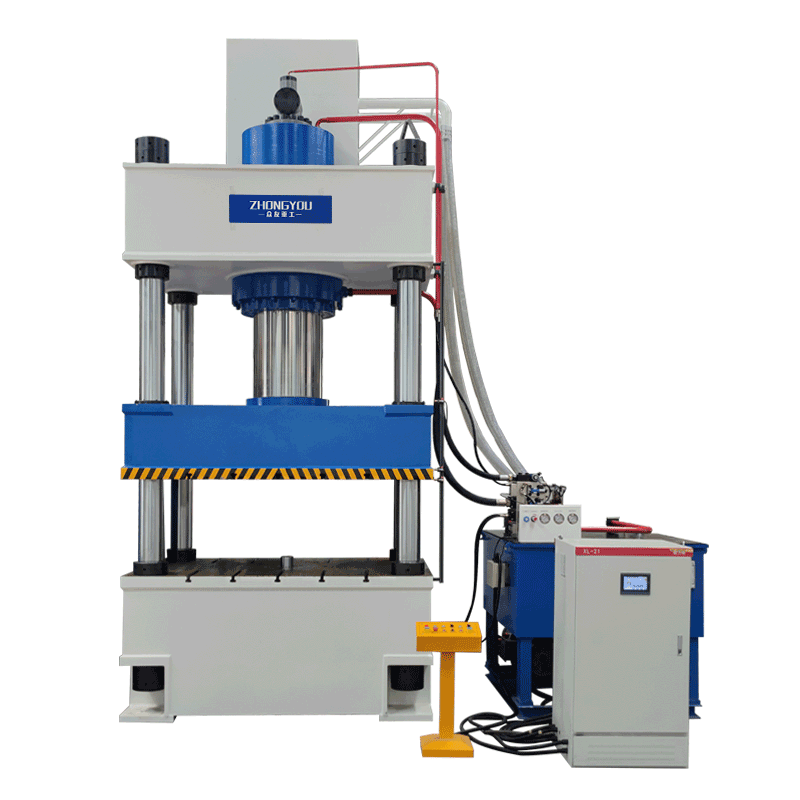

Host machine (800-ton hydraulic press): The core equipment of the production line, which uses strong pressure to press the raw materials into the shape of licking bricks. The hydraulic press has a two-way pressurization function and can produce licking bricks with high density and good licking resistance.

Automatic sealing and cutting machine: Automatically cuts and seals the pressed lick bricks to improve the appearance quality and storage stability of the product.

Conveyor belt: transport the pressed lick bricks to the next process or packaging area.

Heat shrinkable tape: used for packaging licking bricks, fixing the shape of the licking bricks through heating shrinkage, while providing certain moisture-proof and anti-fouling functions.

The 800-ton cattle and sheep brick licking hydraulic press production line has the following advantages:

Efficient production: Able to produce large quantities of high-quality licking bricks in a short period of time to meet market demand.

Stable product quality: Strict process control and high-precision equipment ensure that the quality of each brick is consistent.

Save labor costs: High degree of automation reduces manual operations.

Email: 1959246186@qq.com

WhatsApp: +8613562463338

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| Model | Tonnage | Weight of Molding Salt Brick | Mold | Configuration |

|---|---|---|---|---|

| YZ79-315T | 315 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-400T | 400 tons | 2KG-5KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-500T | 500 tons | 5KG-10KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-630T | 630 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-800T | 800 tons | 10KG-15KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1000T | 1000 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1200T | 1200 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |

| YZ79-1500T | 1500 tons | 10KG-20KG | One-out-one or one-out-two optional | Standard configuration, servo configuration optional |