Round steel calibration C-type single-column presses

250 tons single arm round tube calibration hydraulic press is a kind of machinery and equipment designed for metal tube calibration, its core function is to calibrate the shaft parts such as round tub

+86 13562463338

+86 13562463338

Video Display

Product Introduction

250 tons single arm round tube calibration hydraulic press is a kind of machinery and equipment designed for metal tube calibration, its core function is to calibrate the shaft parts such as round tubes and other shafts accurately by high-pressure hydraulic system, which is suitable for machinery manufacturing, automobile parts, construction hardware and other industries.

Single arm C-shape structure

The machine body adopts open C-shape design, and the single-arm support structure provides a large operating space, which is convenient for workpiece clamping and calibration operation, especially suitable for the calibration of long-size round tubes.

Hydraulic drive system

The hydraulic system drives the piston rod through a high-pressure oil pump, generating a calibration force of 250 tons to ensure the stability and accuracy of the calibration process.The system is usually equipped with pressure and displacement sensors for real-time monitoring of pressure and stroke.

Calibration molds and fixtures

Special molds are designed according to the diameter and wall thickness of the pipe, and the workpiece is fixed by hydraulic clamps to prevent displacement during the calibration process.The molds are usually made of high-strength alloy steel with good wear resistance and long life.

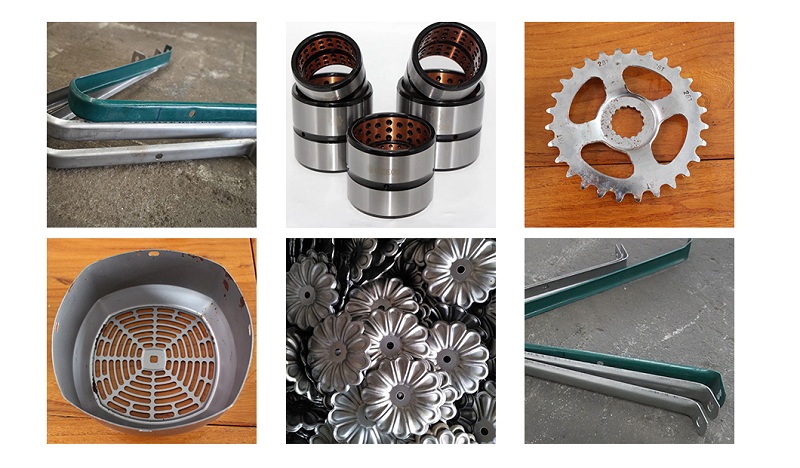

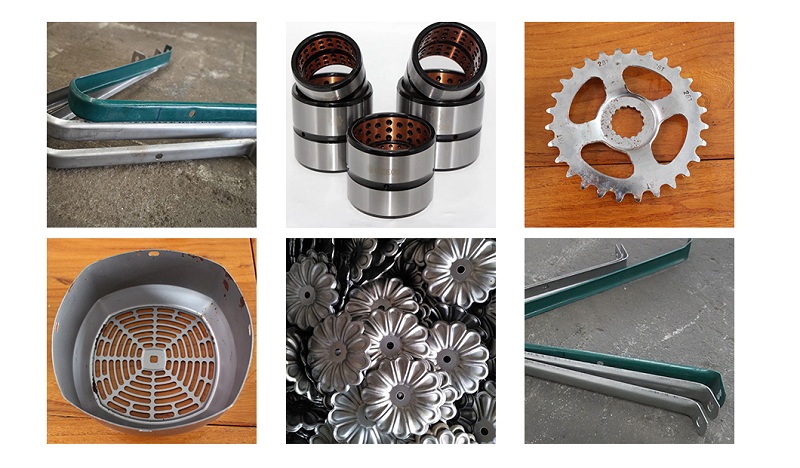

Application Scenarios

Machinery Manufacturing: Correct the bending of round tubes caused by processing or transportation to ensure the accuracy of parts assembly.

Automobile parts: calibrate key parts such as automobile exhaust pipes and transmission shafts to improve product quality.

Architectural hardware: calibrate steel pipes and scaffolding pipes for construction to ensure construction safety.

Aerospace: calibrate high-precision round tube parts to meet the stringent shape and position tolerance requirements.

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |