Small single-arm hydraulic presses press-fit bearings

Single-arm hydraulic press (also known as single-column hydraulic press or C-type hydraulic press) is a widely used in the industrial field of pressure processing equipment, with its compact structure

+86 13562463338

+86 13562463338

Video Display

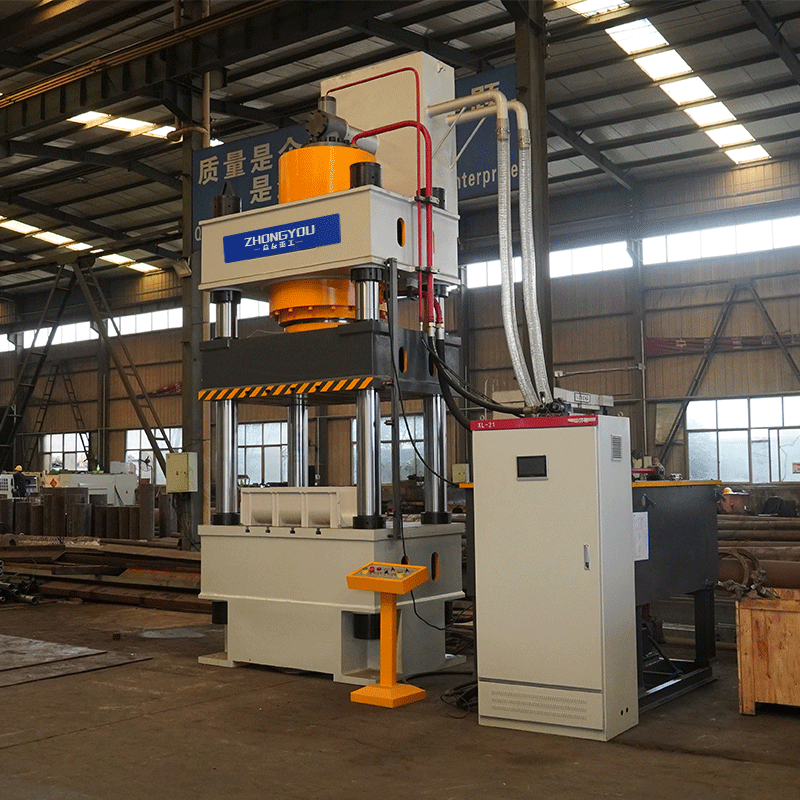

Product Introduction

Single-arm hydraulic press (also known as single-column hydraulic press or C-type hydraulic press) is a widely used in the industrial field of pressure processing equipment, with its compact structure, flexible operation, functionality, etc., has become an important tool for metal processing, plastic molding, powder metallurgy and other industries

Single arm hydraulic presses are of C-type single arm structure, the body is usually made of high strength steel plate welded and vibration treated to ensure rigidity and prevent deformation.Its core components include:

Hydraulic system: It consists of hydraulic pump, hydraulic cylinder, control valve, oil tank, etc. It transmits pressure through Pascal's law and drives the piston to complete the action of pressing and stretching.

Mechanical part: including working table, pressure plate, guide column, etc., used to fix the workpiece and transfer pressure.

Control system: it adopts push button or PLC control, which can realize the functions of fixed range, fixed pressure, automatic/manual switching, etc. Some models are equipped with touch screen or grating protection device.

Main Features

High Rigidity and Stability: Integral welded structure ensures the rigidity of the machine body while providing spacious operating space.

Precise control: Adjustable pressure, stroke and speed for different process requirements, such as stamping, calibrating and press fitting.

Safety and Reliability: Equipped with safety valve, emergency stop button, and grating protection to prevent overload or misoperation.

Versatility: suitable for metal stretching, plastic pressing, shaft alignment, powder metallurgy and other processes.

Low noise and energy saving: adopting high-pressure hose and optimized hydraulic circuit design to reduce operation noise and energy consumption

Technical Parameters

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

Pressing process

Customer Case

Technical Parameters

| Name | Unit | YQ41-20 | YQ41-40 | YQ41-63 | YQ41-100 | YQ41-160 | YQ41-200 | YQ41-250 | YQ41-315 | YQ41-500 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Force | kN | 200 | 400 | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 |

| Effective Stroke | mm | 200 | 200 | 300 | 300 | 400 | 500 | 200 | 500 | 500 |

| Opening Height | mm | 600 | 600 | 700 | 700 | 800 | 1000 | 1000 | 1200 | 1200 |

| Throat Depth | mm | 200 | 220 | 240 | 280 | 320 | 360 | 420 | 500 | 600 |

| Downstroke Speed | mm/s | 160 | 19 | 13 | 10 | 13 | 15 | 15 | 50 | 50 |

| Return Speed | mm/s | 19 | 25 | 17 | 13 | 20 | 20 | 20 | 60 | 55 |

| Worktable Width (Left to Right) | mm | 500 | 500 | 600 | 700 | 700 | 800 | 900 | 1050 | 1200 |

| Worktable Depth (Front to Back) | mm | 400 | 400 | 450 | 500 | 600 | 700 | 800 | 900 | 1050 |

| Punching Hole Diameter | mm | 80 | 100 | 120 | 200 | 200 | 220 | 220 | 240 | 240 |

Pressing process

Customer Case